News

Learn about plywood, coppha plywood

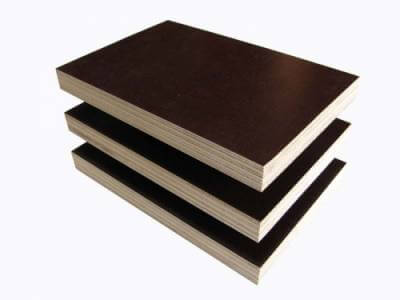

Film Faced Plywood (WBP Film Faced Plywood): This is a new technology product, used in high-end construction projects. The surface is covered with a black or brown film, the intestines are glued together with water-resistant glue during the thermal pressing process.

Formwork plywood has other common names in the construction community such as black board, film board, film coffa board. etc …

Usage: making formwork, pouring concrete

When cutting boards to cast columns or beams, whether the water seepage can damage the board due to the glue. If the manufacturer does not use 100% Phenolic glue, the wood layers will peel off after 2-3 pouring of concrete.

A. GENERAL INTRODUCTION

English names: Film Faced Plywood, WBP Film Faced Plywood, Formwork Plywood, Concrete Plywood

Vietnamese name: Plywood formwork

Other name: no

Is a water-resistant plywood specialized in formwork in the construction industry.

B. CLASSIFICATION

There are 2 main types:

1. Film Faced Plywood (Film Faced Plywood, WBP Film Faced Plywood): This is a new technology, used in high-end construction projects. The surface is covered with a black or brown film, the intestines are glued together with water-resistant glue during the thermal pressing process.

Advantages

Light, easy to install, dismantle

Light, no need to bowl after pouring concrete

Reuse many times

General size:

Thickness: 12-15-18mm

Width x Length: 1220mm x 2440mm

Film-coated plywood is cut out

The main factors determining the quality of Film coated plywood:

1. Glue: this is the most important factor deciding whether the board can withstand water during construction or not.

There are 3 main types:

Phenolic: withstand boiling water for at least 12 hours. The bonding force between the layers of wood is good.

Melamine: withstand boiling water for 4 hours

MR (Urea formaldehyde): Very rarely used pure, but often mixed with Melamine in the following ratio:

12% Melamine and 88% MR

15% Melamine and 85% MR

This type is quite popular in the Vietnamese market.

When cutting the board to cast the column or momentum, whether the water seepage can damage the board due to the glue. If the manufacturer does not use 100% Phenolic glue, the wood layers will peel off after 2-3 pouring of concrete.

2. Plywood & Heat Laminate: This is the deciding factor for durability and bearing capacity.

There are 3 main types of ingredients for making intestines: tropical hardwood, coconut and Aries. Two types of tropical hardwood and coconut are very expensive, not popular in Vietnam.

There are 3 types of gut quality:

Type A: connect up to 4 panels lengthwise. The wood is dried for 20 minutes, heat pressed for 30 minutes, has good bearing capacity, and is less likely to be hollowed out (puffiness).

Type B: connect up to 8 panels lengthwise. Wood is dried for 10 minutes, heat pressed for 10 minutes.

Type C: unlimited joints. The wood is dried for 10 minutes, heat pressed for 10 minutes, the intestines have many holes.

The drying and heat pressing process both increases the adhesion of the glue and increases the strength of the board.

Plywood force: minimum 120 tons / m.

The two sides of the board must be rubbed with 240 sandpaper before covering the film.

3. Film: is a thin plastic film that creates gloss, limits scratches on the surface of the board, before covering the board through the heat pressing process, it must be kept in a cold storage.

There are 2 colors:

Brown film: mainly imported from Finland. This is the leading exporter of Film used as formwork in the world.

Black Film: The market mainly uses Black Film made in China.

The quality of Brown Film and Black Film is different, thus affecting the quality of the surface of the board.

HOW TO TEST THE QUALITY OF FILM COALS:

If you leave the plank, it is difficult to distinguish the quality with the naked eye. Besides testing by modern means, the simple way to check the quality of plywood is:

Check the quality of intestines: cut the board, if there are many holes, the gut is type B or C

Test glue quality: Boil in boiling water for 5 hours. If the laminate and film layers come off, the glue is not a phenolic glue

Distinguishing hardwood and softwood: If the board is made of hardwood, the following parameters are available:

Density 550kg / m3

Weight of 18mm thick boards> 38kg

Weight of 15mm thick boards> 34kg

Weight of thick board 12mm> 28 kg

PRESERVATION FILM FILM

Do not let the formwork slip or fall from above

Dry the formwork surface before storing

Let the formwork lie on the floor surface

Clean both sides of the formwork after use

Apply oil after 3-4 times of use.

Putty in the nail holes.

The products that our company is providing in the market today are:

– Rubber Grafting Wood

– Veneer Grafted Wood

– Que Grafted Wood

– Grafted Wood

– Grafted wood

– Carpentry Moc Moc

– Imported MDF

– Veneer MDF

– MDF Smooth

– MDF Vietnam

– Okal Chong Moist

– Okal Covered with Van Wood

– Okal Melamine Coating (MFC)

– Okal Covered Veneer

– Plain Okal

– Brown Film Coated Coffa Board

– Black Film Coated Coffa Board

– Bamboo Coffa Covered Film

– Red Coffa game

– Water Resistant Plywood

– Imported Plywood

– Common Plywood

– Plywood for pallet making

– Plywood covered with transparent glue

– Plywood for packing

– Laminate furniture

– Laminate formica